PIPE LIFTING CLAMPS

30 August 2022

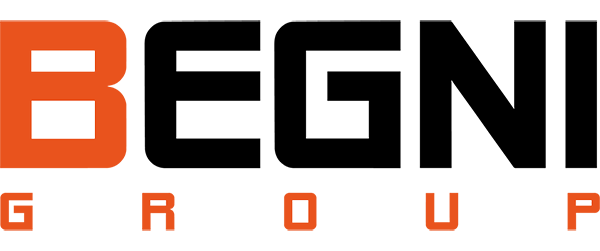

HORIZONTAL LIFTING CLAMPS

30 August 2022BEGNI GROUP COBRA® LC, DFM, TMS and YDG tough quality lifting clamps guarantee a high performance and a long operational life.

They have specifically been designed for the horizontal lifting and transporting of steel beams.

The cam also functions as a lifting shackle and ensures that the load is held firmly while it is being lifted.

They have “heavy duty” welded shell bodies, made of high high-quality carbon steel. The cam is made of steel alloy, high frequency hardened for a greater durability. The lightweight and streamlined design make them easier to handle. They meet all standards and requirements such as: European Standard EN13155 and European Machine Directive 2006/42/CE.

They are available in 4 types:

Choose the clamp according to the WLL, the opening, the size.

LC

Clamp designed for lifting and transport of steel beams.

WLL up to 3 ton.

DFM

Clamp designed for lifting and transport of steel beams.

WLL up to 3 ton.

TMS

Clamp designed for lifting and transport of steel beams. Handle makes easy and safe to set and detach the clamp onto and from the work piece.

WLL up to 3 ton.

YDG

Clamp designed for lifting and transport steel beams in horizontal and vertical position. The beam resting on the flanges can be lifted and moved horizontally.

WLL up to 2 tons.

- Quality steels: BEGNI GROUP COBRA® LC, DFM, TMS and YDG clamps are made of top-quality steel and fully comply with European Standards in Machine Directive 2006/42/CE.

- Large stock in the warehouse: the wide availability of products allows very fast delivery times to process even the most urgent orders.

- Tech for Safety: it is possible to apply an NFC-RFID microchip for digital product management (traceability, inspections, maintenance).

- Working temperatures: -40°C +100°C

- Compliant with DM2006/42/CE and EN13155.

Before using the products, carefully read the safety instructions.

For further information, please contact us: our sales technicians will indicate you the most suitable products for your applications.

- Never lift loads heavier than the WLL., as indicated on the clamp and on the certificate.

- Minimum WLL is 10% of Max WLL as indicated on the clamp and on the certificate.

- Do not lift pieces which are thicker or thinner than the jaw opening, as indicated on the clamp and on the certificate.

- Take care when lifting from a non-vertical position. The working load limit (WLL) may be considerably reduced in these lifting situations.

- The surface of the material must have a hardness level of max. HrC 37/345 Hb.

- Avoid free falls or hitting objects of the clamp.

Before using the products, carefully read the safety instructions.

For further information, please contact us: our sales technicians will indicate you the most suitable products for your applications.